automotive

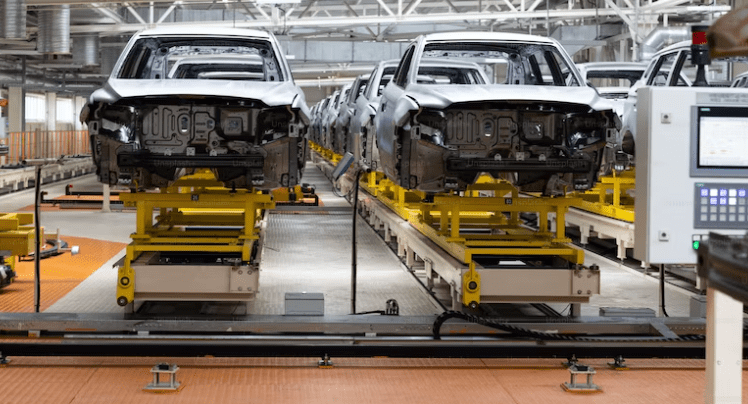

Increase possibilities of scalable quality control

meet the high quality industry requirements

AI vision technology in the automotive industry offers numerous applications such as real-time defect detection and quality control, including crack and anomaly detection, leak detection, and object classification. Additionally, it enhances safety compliance by identifying hazards, monitoring safety protocols, and alerting potential risks for a safer manufacturing environment.

Applications within your industry for computer vision

Quality control and defect detection

Our AI vision technology enables real-time inspection and detection of defects, ensuring high product quality and reducing the risk of faulty or non-compliant items reaching the market.

Safety compliance and hazard detection

Our platform enhances workplace safety by identifying safety hazards, monitoring compliance with safety protocols, and alerting potential risks, leading to a safer manufacturing environment.

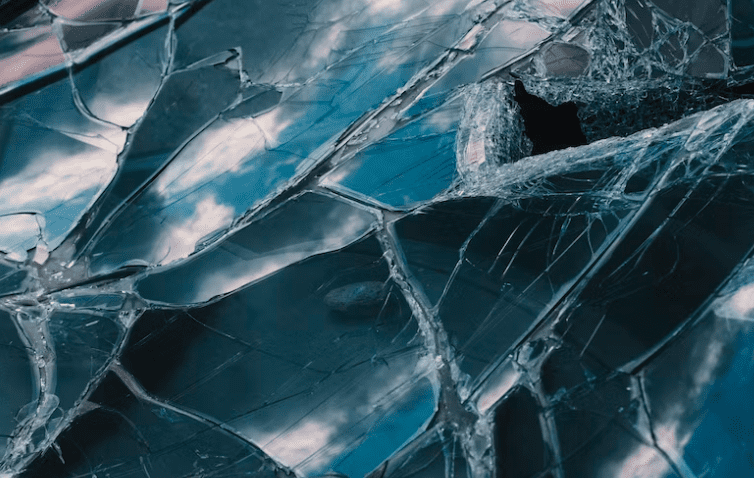

Crack Detection

Computer vision algorithms can be trained to detect cracks on various automotive components such as engine parts, chassis, windshields, or other critical structures. By analyzing images or video streams, these algorithms can identify and locate cracks, enabling early detection and preventing potential failures or accidents.

Anomaly Detection

Computer vision techniques can be employed to identify anomalies or irregularities in automotive manufacturing processes. By analyzing patterns and comparing them against expected norms, the system can detect deviations, such as missing or misplaced components, incorrect assembly, or other abnormalities, ensuring that only high-quality products are released.

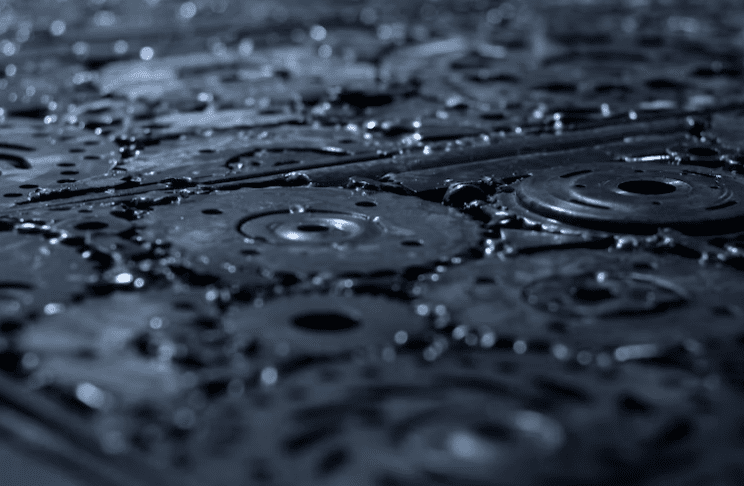

Leak Detection

Computer vision can assist in detecting leaks in automotive systems such as fuel lines, hydraulic systems, or coolant circuits. By visually analyzing components or using thermal imaging, the system can identify leaks based on changes in fluid flow, temperature, or visual cues, allowing for timely repairs and avoiding potential malfunctions.

Surface Inspection

Computer vision can be employed for the inspection of automotive surfaces to identify defects, scratches, or imperfections. By analyzing images or using 3D scanning techniques, the system can detect surface irregularities, ensuring high-quality finishes and minimizing customer complaints.

we promise, you’ll be on your way in less than 10 minutes.

For system integrators and security/operations leaders who need to deliver AI results in 30 days.

in just 10 minutes you’ll

be on your way:

end-users

for integrators

Book a 20‑minute use‑case consult

Join our partner program