AI Control Room Automation: Purpose-built Systems for 2025 and Beyond

Control rooms in factories, grids, and transport hubs now face more signals than a person can follow. AI Control Room Automation offers purpose-built software and hardware that handle this load. First, these platforms ingest real-time data and correlate events to present an explained incident, not just an alarm. Then, they rank incidents and recommend actions so the operator’s attention lands where it matters. visionplatform.ai turns camera feeds into searchable context and reasoning, which helps operators monitor events with fewer screens and clearer priorities. The result is that teams and slack notifications deliver meaningful messages rather than noise, which helps to boost productivity and reduce operator fatigue.

Purpose-built platforms share key characteristics. They combine a Vision Language Model and AI agents that reason over video, VMS logs, access control, and procedures to verify alerts. They run on-premise to avoid data leaving the site, which aids compliance and reduces vulnerability. They offer enterprise-ready connectors to DCS and SCADA, and they expose telemetry for dashboards and orchestration. They also support an onboarding path from pilot to full deployment for end users, with audit logs across the lifecycle. For customers who worry about cloud dependency, an on-prem option gives full control while still allowing integrations with AWS where permitted.

ROI projections for 2025 favor early adopters. Studies show high-level leadership increasingly interacts with generative tools, and AI-assisted automation could unlock trillions in economic value over the coming decade 53% of C-suite leaders interact with generative AI. Companies that deploy AI in control rooms report measurable reductions in false alerts and faster mean time to respond, which reduces significant downtime and cuts operational cost. A 2025 McKinsey projection estimates that AI-powered agents and robots could create roughly $2.9 trillion of value by 2030 in the US, with control room use cases contributing to that figure AI: Work partnerships between people, agents, and robots.

Early deployments in manufacturing and energy show practical gains. In manufacturing, AI-assisted video search and forensic tools reduce time to investigate incidents and increase throughput on lines. In energy, early pilots with AI that bridges sensor networks to enterprise systems improve predictive maintenance and reduce unplanned downtime. For example, combining traditional SCADA alarms with contextual video verification reduces false positives and lets the control room operators focus on real emergencies. As Dr. Emily Chen said, “AI-driven control room automation is not about replacing human operators but augmenting their capabilities, enabling faster, more accurate decisions in high-stakes environments” Future of Work with AI Agents. These systems are purpose-built to support the operator’s role while scaling monitoring across multiple sites.

End-to-End AI-Powered Workflow Optimisation in Complex Systems

End-to-end AI workflows stitch together data flows from sensors, cameras, VMS, and business systems to create continuous operational value. An end-to-end pipeline starts with robust ingestion, then processes and enriches raw signals with contextual metadata, and finally pushes actionable alerts to the right teams. This design reduces handoffs and eliminates redundant manual steps in the workflow. visionplatform.ai implements this by converting video into human-readable descriptions, which makes forensic search practical and lets AI tools reason over events.

In multi-site operations, a single orchestration layer coordinates local agents and a central dashboard. That layer executes rules, escalates incidents, and recommends corrective actions. It also handles role-based permissions so that human operators retain final approval for risky steps. By design, the platform supports both automated low-risk closures and human-in-the-loop decisions for high-risk scenarios. This balance assures that systems automate routine verification while humans retain oversight for exceptions. The approach helps teams accelerate incident closure and improve operational excellence.

AI-powered modules streamline data ingestion by normalising timestamps, mapping fields, and linking events to historical data. They then apply machine learning to spot contextual anomalies and to predict component failure. This results in fewer nuisance alarms and clearer, more actionable alerts delivered to the right teams. For example, when a camera detection matches access-control logs and environmental sensors, the system raises a validated alert instead of an unverified alarm. The platform can also pre-fill incident reports to reduce manual entry, which helps to boost productivity while preserving auditability.

Handling complex system interdependencies requires that the AI understand causal links and dependencies across distributed control nodes. A distributed control system speaks with edge agents that feed a central reasoning engine. The engine uses historical data and digital twins to model how a single fault might cascade through the complex system. Metrics for success include reduced false positives, a drop in mean time to acknowledge, and measurable increases in throughput. Real metrics to track are incident reduction, increase throughput, reduced significant downtime, and time saved per investigation.

AI vision within minutes?

With our no-code platform you can just focus on your data, we’ll do the rest

Machine Learning Analytics to Bridge Data for Grid Operator and Energy Producers

Machine learning analytics plays a central role in connecting disparate data sources for grid operator workflows and for energy producers. A bridge between sensor networks, SCADA, VMS, and enterprise systems lets teams unify telemetry and historical data. This bridge enables models to forecast demand, detect anomalies in generation, and suggest redispatch actions. As a grid operator makes decisions, they gain access to contextual video verification and to predicted outputs from wind turbines and other assets.

Building the bridge starts with normalising real-time data feeds and tagging them with consistent identifiers. The analytics layer then computes short-term forecasts using historical data and real-time data. Models can predict generation shortfalls or overproduction and recommend load adjustments. For energy producers the same analytics pipeline helps to optimize dispatch and reduce fuel costs. In both cases, the system uses digital twins to simulate potential corrective actions before they are applied.

Use cases include demand forecasting, output optimisation for distributed wind turbines, and anomaly detection for thermal and mechanical systems. A combined sensor and video approach lets operators monitor plant operations visually while models surface subtle degradation patterns. This reduces significant downtime and improves load balancing. When an anomaly arises, the analytics engine provides actionable insights and recommends corrective actions with probabilities based on past events.

Measurable gains are real. Operators report fewer unplanned outages, faster incident triage, and improved load factor across energy resources. The platform enables plant operations teams to deploy AI-assisted maintenance windows and to reschedule tasks based on predicted failures. This approach helps avoid unnecessary inspections and aligns maintenance with actual equipment condition. For grid management, better forecasting reduces curtailment and supports more efficient use of energy resources, which ultimately lowers operating cost for both grid operators and energy producers.

AI Agents and Agentic AI: Automate Monitoring for Full Control

AI agents now take on routine surveillance, triage anomalies, and present verified incidents to human teams. Agentic AI extends beyond simple rule engines by reasoning over multiple inputs and by recommending or executing actions under defined policies. These agents can automate surveillance tasks to maintain 24/7 oversight while ensuring the operator retains full control of critical decisions. visionplatform.ai ships agents that reason over video descriptions, VMS events, and procedural documents so alerts come with context and justification.

Automate low-risk responses and human-in-the-loop higher-risk decisions. The VP Agent Actions feature lets the control room choose when to allow autonomous closures and when to queue an alert for human review. This design ensures that systems act quickly on routine incidents while always offering escalation paths. For high-risk environments like petrochemical plants, agents can run continuous checks and notify the right engineers when a verified anomaly suggests immediate attention. In these settings, the presence of a human on the loop keeps sensitive operations safe and ensures the operator’s role remains central.

Agentic AI must be transparent and auditable. To ensure trust, the agents log every reasoning step and every action they propose. They also expose confidence scores and the data that drove a decision. This transparency reduces vulnerability concerns and aligns with cybersecurity requirements. It also helps teams and slack channels receive only validated, contextual alerts instead of raw detections.

A real-world example comes from continuous monitoring at a petrochemical site. There, AI agents correlate leaks seen on video with pressure drops in the DCS and with access logs. The system then recommends containment steps and a sequence of corrective actions. The operator receives a concise, explained incident that supports right decisions under pressure. Operators monitor ongoing remediation through a central dashboard, and they can hand control back to the agent for low-risk follow-ups.

AI vision within minutes?

With our no-code platform you can just focus on your data, we’ll do the rest

Enterprise AI and Digitalization: AI Control for Seamless Management

Enterprise AI becomes the backbone of digitalization by linking local control nodes to central reporting and governance. An enterprise-level dashboard unites telemetry, video insights, and incident histories so leaders can track KPIs and operational excellence across sites. The architecture supports enterprise-ready connectors, secure APIs, and role-based access for end users. This centralisation helps teams make informed decisions rapidly and ensures consistent procedures across plants.

Integrating legacy DCS and distributed control equipment demands careful planning. Seamless integration requires adapters that map legacy tags into modern schemas and that publish events for orchestration. A modern automation platform should not rip out existing control systems; it should add a reasoning layer that shows why an alert matters and what the likely impact will be. For example, connecting to a distributed control system lets the AI correlate pressure trends with video events and to recommend whether a field crew should inspect a pump.

Governance and change management are crucial when you deploy AI at scale. Operators need trust, so transparent models, audit trails, and a gradual onboarding path matter. Training and reskilling programs help shift roles from manual control to supervision and exception handling. With the right approach, enterprise AI reshapes daily operations and helps operational teams increase throughput while reducing significant downtime. As one Microsoft AI leader put it, “By leveraging AI to automate data analysis and routine tasks, control rooms can focus human expertise on strategic decision-making, driving both safety and efficiency gains” AI-powered success—with more than 1,000 stories.

To be enterprise-ready, solutions must meet cybersecurity standards and minimize data exfiltration. visionplatform.ai keeps video and reasoning on-premise by default so that customers maintain data ownership and can meet compliance such as the EU AI Act. This approach supports governance and prevents common vulnerabilities associated with cloud-based video processing.

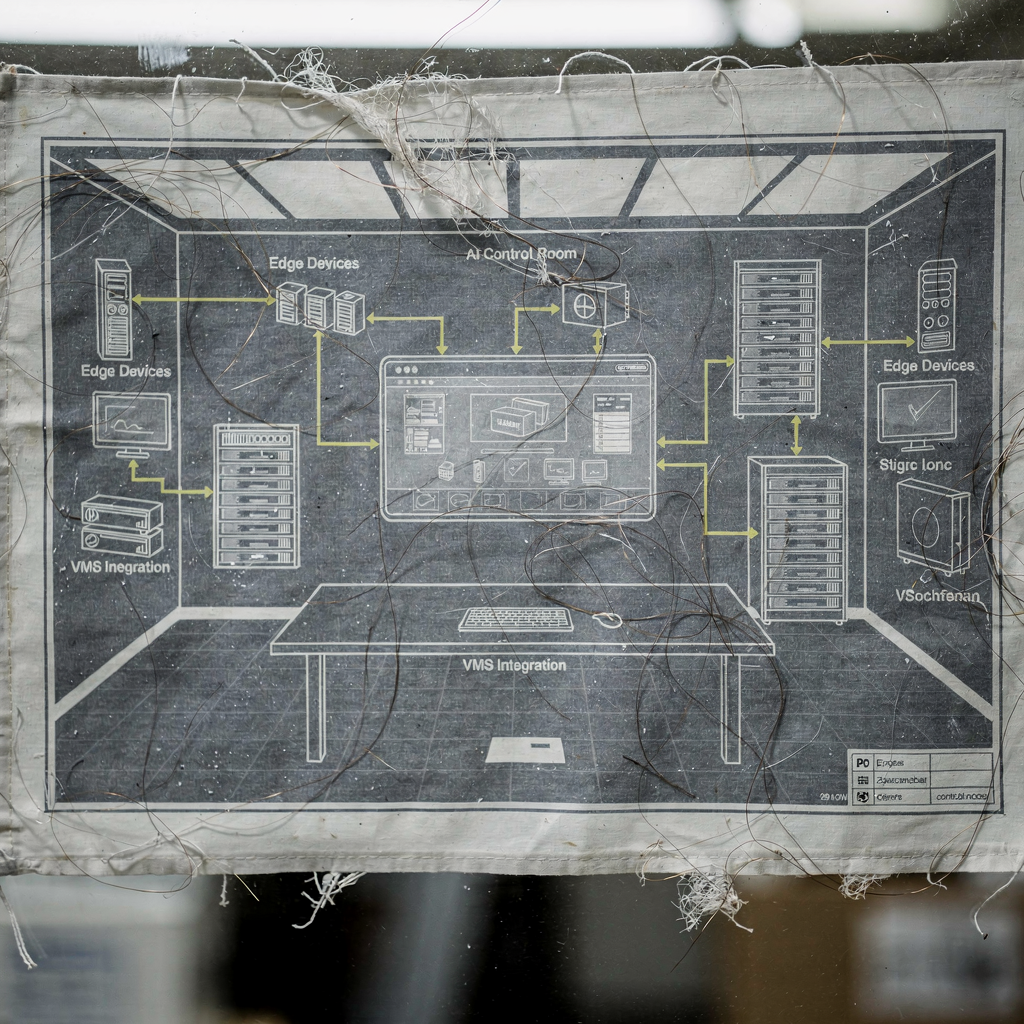

Building an AI Control Room with Artificial Intelligence and Powered by AI Technologies

An architectural blueprint for an AI control room starts with sensors and cameras at the edge, flows through local inference nodes, and culminates in a central reasoning engine. Core components include predictive engines that use historical data, alert managers that prioritise incidents, and visual analytics that present actionable insights. You must choose whether to run models on-premise or to use cloud services like AWS; that choice affects latency, compliance, and scale.

Predictive engines use machine learning models trained on historical data and labeled incidents. They forecast failures, help to optimize maintenance windows, and reduce downtime. Visual analytics provide operators with contextual views that combine camera clips, sensor trends, and procedural steps. An automation platform coordinates actions, and it can trigger workflows in enterprise software. The design should support digital twins to simulate real-time decision-making before committing to high-impact actions.

When you deploy AI, start small and then scale AI across sites. Pilots validate model performance on actual plant operations and provide data for reskilling the workforce. A clear lifecycle for models—from training, validation, deployment, and retraining—keeps performance consistent. Use robust onboarding for end users, and design interfaces so that operators monitor critical KPIs without distraction. Teams should include site engineers, IT, and the right teams for governance and incident review.

Security matters. Cybersecurity practices must protect model inputs and video streams from tampering. Architectures that keep sensitive material on-premise reduce data exposure and support enterprise compliance. Also plan for integration with existing SCADA and DCS to avoid replacing proven control systems. The final system should allow operators to remain in full control while letting agents handle low-risk repetitive tasks. If you want to deploy AI across a campus of plants, ensure your orchestration layer can scale AI models and manage updates automatically.

As the market adopts these platforms, enterprise AI will reshape how teams handle daily operations. Real-world deployments already show that AI-enabled reasoning cuts investigation time and helps teams make informed, actionable decisions. Companies that invest in transparent AI systems, strong onboarding, and rigorous governance will find that their control rooms can both increase throughput and reduce significant downtime while ensuring that there will always need a human available for high-risk choices.

FAQ

What exactly is AI control room automation?

AI control room automation uses AI to monitor, analyse, and sometimes act on operational data coming into a control room. It reduces manual steps and improves situational awareness by turning raw signals into contextual alerts and recommendations.

How do AI agents differ from traditional software in a control room?

AI agents reason over multiple data sources and can suggest corrective actions or execute low-risk workflows autonomously. Traditional software usually triggers static alarms, while agents provide contextual explanations and confidence scores for decisions.

Can AI systems replace human operators?

No, most modern designs emphasize human-in-the-loop oversight so that humans approve high-risk actions. AI-assisted systems aim to augment human expertise rather than replace the operator’s role.

How does visionplatform.ai handle video privacy and compliance?

visionplatform.ai processes video on-premise by default, keeping footage and models inside the customer environment to reduce data exposure. This design supports compliance with regulations such as the EU AI Act and lowers vulnerability to data leaks.

What are typical measurable benefits of an AI control room?

Benefits include fewer false alerts, quicker incident triage, reduced downtime, and increased throughput. Organisations also report faster forensic investigations thanks to searchable video and contextual reasoning.

How do you integrate AI with legacy DCS and SCADA?

Integration uses adapters that map legacy tags into modern schemas and publish events to the AI layer. This lets enterprise AI reason over both historical data and real-time data without replacing existing control systems.

Is agentic AI safe for critical infrastructure?

Agentic AI can be safe if it follows strict policies, has auditable logs, and keeps human-in-the-loop options for risky operations. Safety also depends on cybersecurity controls and on limiting autonomous actions to low-risk scenarios.

What role do digital twins play in an AI control room?

Digital twins simulate plant operations so teams can test corrective actions before applying them. They help to predict cascade effects in a complex system and to validate informed decisions under different scenarios.

How should organisations prepare staff for AI-enabled control rooms?

Organisations should provide reskilling and practical onboarding that focuses on oversight, exception management, and understanding AI reasoning. Training should include how to interpret confidence scores and how to audit agent decisions.

What kinds of industries benefit most from AI control room automation?

Energy, manufacturing, transportation, and petrochemical plants benefit significantly because they operate complex systems and face high costs from significant downtime. Any sector with distributed assets and continuous monitoring needs can gain value from AI-driven control room automation.