detection systems and sensor technologies in manufacturing

Manufacturing plants must monitor many hazards. They do so with a variety of detection systems. These range from simple heat detectors to complex networks that combine vision, point sensors and analytics. In industrial environments the goal is to identify a hazard quickly and act. Early detection reduces property damage and keeps people safe. For example, industry research shows the flame and smoke detectors market reached about $6.3 billion in 2023 and continues to expand as manufacturers adopt advanced solutions (BCC Research).

Common detection systems in industrial settings include point detectors, aspirating pipelines, beam detectors and camera-based analytics. Photoelectric detectors and ionization detectors serve complementary roles on production floors. In large open warehouses beam detectors can cover long spans. In confined spaces heat detectors remain a core element for detecting high temperatures. Each type helps to detect the presence of smoke particles or rising heat before a full alarm triggers. The best designs mix technologies to reduce false alarms while keeping sensitivity high.

Sensor networks tie individual devices into broader life safety and operations platforms. They link to control panels and facility management for coordinated responses. Site teams can then see sensor health and calibrate units on schedule. This approach also supports compliance with safety regulations and audit preparation. For example, a recent industry analysis emphasises that “The integration of advanced smoke detection technologies in manufacturing plants is not just a regulatory requirement but a vital investment in operational continuity and worker safety” (IBISWorld).

Market data shows adoption of networked detectors and smart sensors is rising. FactMR projects the fire alarm and detection market will reach USD 33.56 billion by 2025 (Fact.MR). In practice, manufacturers often combine fixed-point detectors with camera analytics. Visionplatform.ai helps here by turning existing CCTV into operational sensors so cameras stream events to your VMS and to operations systems. This approach reduces installation costs and improves detection capabilities while keeping data local and auditable. For more on camera-based operational detection, see our work on fire and smoke detection in airports.

smoke detection and thermal sensors: methods and applications

Photoelectric detectors and thermal sensors each target different signs of fire. Photoelectric detectors excel at sensing early stages of combustion by registering the presence of particles of combustion in the air. thermal sensors, including thermal imaging cameras, detect temperature changes and can identify high temperatures before smoke appears. Photoelectric detectors took a 34% market share in 2024 for smoke technologies, reflecting their strength in identifying smouldering fires (Mordor Intelligence).

When processes involve flammable powders, lubricants or hidden smoulder sources, a smoke detection solution that senses particles early is critical. Aspirating systems, which draw air samples through tubing, detect the earliest traces of smoke and thus provide important lead time. In fact, aspirating or air sampling smoke detection is ideal for high-value or high-risk production areas. Aspirating designs draw air samples to a central detector and trigger an alert before visible smoke develops. These systems lower response time and enable earlier intervention.

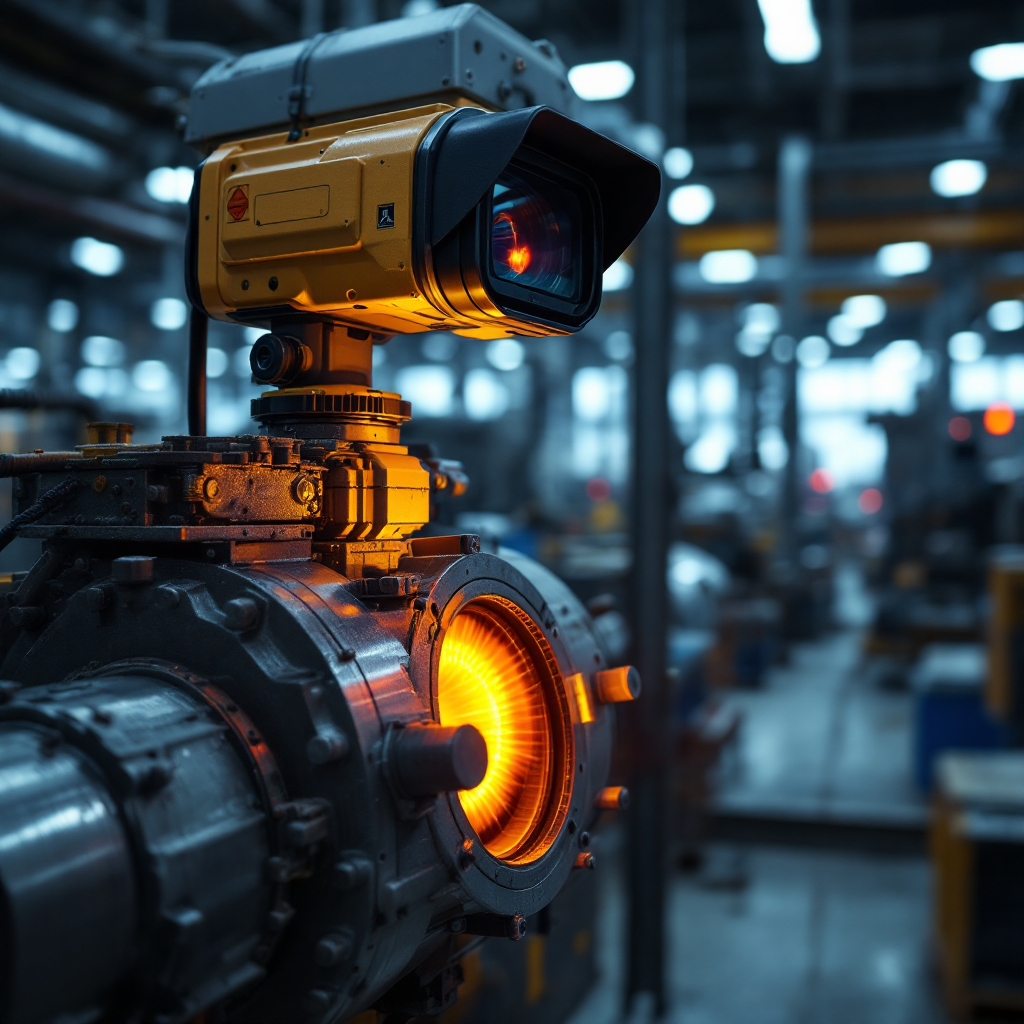

Thermal imaging cameras add value where visual smoke can be masked by dust or steam. They detect heat patterns and can detect temperature anomalies across equipment, motors and stored goods. Thermal imaging supports predictive maintenance too. For example, a bearing overheating shows as a temperature change before a developing fire. Combining thermal sensors with smoke detectors and visual analytics reduces false alarms and improves identification of potential fire hazards. In practice, teams configure sensitivity and set thresholds so the system triggers an alarm only when it must.

Performance metrics here focus on sensitivity, false-alarm rate and response time. Designers balance detect thresholds to avoid nuisance alerts without delaying notification for a developing fire. For battery energy storage systems and other new risks, the right mix of smoke and thermal sensing matters. Video smoke detection can complement point devices in large industrial environments. For a practical example of how camera-based sensing powers operations beyond alarms, read our page on process anomaly detection, which shows how visual data can be operationalised.

AI vision within minutes?

With our no-code platform you can just focus on your data, we’ll do the rest

fire detection and detect capabilities for rapid hazard response

Manufacturers rely on a mix of ionization, optical and combined fire detection techniques. Ionization detectors react quickly to fast flaming combustion. Photoelectric detectors better detect smouldering fires. Combining both types gives broad coverage. Ionization detectors and photoelectric detectors address different particles of combustion and light intensity patterns so facilities can spot a range of developing threats. Use of dual-technology units supports effective fire detection while limiting false alarms.

Detect thresholds and average response times shape system performance. Facilities configure thresholds to balance early detection with practical false-alarm tolerances. For instance, setting a lower threshold helps detect the earliest smoke but increases false alarms in dusty processes. Design teams therefore map risk, process emissions and ventilation before finalising settings. In many plants automatic fire responses link detection to suppression. When a detector senses smoke or heat beyond a set threshold, it can trigger an alarm and activate fire suppression systems or other mitigation steps. This automation can extinguish small flames and slow fire spreads while emergency teams mobilise.

Integration matters. Systems integrate with control panels, alarm notification platforms and building management systems so teams get coordinated information and can act fast. Control panels collect inputs and drive outputs. They also log events for post-incident analysis and insurance audits. For high-value lines we often add video verification. Video verification helps operators identify signs of fire visually and decide whether to escalate. Visionplatform.ai converts cameras into sensors that publish structured events to your security stack and to operations dashboards, reducing false detections and speeding informed decisions.

Regulators expect reliable fire protection and fast response. Standards guide deployment and testing so life safety requirements are met. Facilities must test detectors, train staff and update response plans regularly. This ensures the system performs as expected during a malfunction or during an actual fire. For an example of combining thermal monitoring and visual analytics, see our thermal people detection work, which shows how thermal imaging merges with video analytics for safety-sensitive sites.

fire detection system and fire and smoke detection integration

Designing unified fire detection system architectures requires a clear risk map. Start by identifying fire hazard zones, combustible inventories and critical assets. Then choose complementary detectors and plan cable runs, power redundancy and control panels. Systems are designed so alarms and suppression activate in a coordinated, auditable way. This reduces response time and improves outcomes for people and property.

Compliance with NFPA, EN and local codes forms the backbone of any installation. These standards set detection of smoke and flames thresholds, placement of detectors and testing cadences. They also require documentation for commissioning. Inspectors look for proper operation, calibration records and evidence that systems perform under fault conditions. A unified architecture simplifies audits and keeps life safety systems consistent across sites.

Multi-site manufacturers often deploy a standard baseline and then tune systems for local risks. Case studies show that linking sites to central monitoring and sharing detection capabilities delivers faster, standardised responses. For instance, a multinational plant may standardise on photoelectric detectors in storage areas but add aspirating lines where smouldering risks exist. Centralised event logging also supports insurance conversations and risk reduction planning.

When integrating camera analytics, choose solutions that respect data locality and compliance. Visionplatform.ai provides on-prem, edge-first analytics so video stays under customer control. This approach supports GDPR and the EU AI Act readiness while expanding sensing beyond traditional detectors. Combining video smoke detection with point detectors creates a seamless detection fabric. It also helps teams identify a fire visually and confirm alerts before wide-area suppression activates. Finally, plan for maintainability. Scheduled testing, timely replacement of consumables and clear maintenance contracts keep systems reliable over time.

AI vision within minutes?

With our no-code platform you can just focus on your data, we’ll do the rest

early fire detection with edge ai analytics

Edge AI transforms how teams detect early warning signs. Instead of sending all video to the cloud, analytics run on edge devices to provide real-time alerts. This reduces latency and keeps data on-prem for compliance. For companies that already have CCTV, turning cameras into sensors is a cost-effective path to broader coverage. Visionplatform.ai offers that capability, so you can stream events to dashboards and publish alerts into SCADA or BMS systems.

Machine-learning models can identify anomalies that precede a developing fire. Models learn normal thermal patterns, detect temperature anomalies on motors, and spot unexpected smoke plumes. They can also identify signs of malfunction in conveyors or ovens that otherwise lead to combustion. By combining visual cues with point sensor inputs, systems detect the earliest deviations and provide an early warning so teams intervene.

Edge ai reduces false alarms by running customised models that match site conditions. Off-the-shelf detectors often trigger in dusty or high-ventilation environments. Custom models, trained on local footage, filter benign events while keeping sensitivity to real hazards. This improves detection capabilities and lowers operational disruption. In practice, models publish simple events over MQTT so both security and operations can consume them. That seamless flow helps teams act fast and reduces unnecessary shutdowns.

Operational benefits include lower downtime, faster incident verification and improved fire prevention. Analytics also create searchable event logs for post-incident review and insurance purposes. For battery energy storage systems or flammable chemical lines, combining thermal imaging cameras with bespoke models gives early cues of hotspots before a full automatic fire response is needed. Overall, AI-enhanced sensing helps identify a fire early and provides the context operators need to act decisively.

detection optimisation: fire risk management and compliance

Optimising detection means more than choosing the right detectors. It requires routine testing, calibration and lifecycle planning. Scheduled testing keeps units within tolerance and reduces false alarms. For example, many standards call for documented functional tests and replacement of sensing elements at set intervals. Maintenance teams should maintain logs in control panels and ensure proper operation between tests.

Regulatory requirements drive many decisions. Inspectors expect calibrations, documented repairs and evidence that systems meet safety regulations. Use vendor-recommended test regimes and record everything. Audit readiness also depends on lifecycle data for detectors and suppression devices. Facilities that can rapidly produce logs and event histories lower insurance friction and get faster claim resolution.

Detection data can also inform risk assessments. Trend analysis of near misses, nuisance alerts and sensor faults highlights areas for design change. For example, repeated high-temperature warnings around a motor can trigger a maintenance action that prevents a developing fire. Using data in this way turns life safety systems into operational tools for fire prevention. Beam detectors, photoelectric detectors and thermal sensors each produce data that, when combined, create a comprehensive fire picture.

Finally, plan for resilience. Redundant power, zoned suppression and verified communication paths ensure that an alarm will trigger an appropriate response. Train teams on response procedures and run drills so staff know how to react when an alarm or alert fires. With a solid maintenance and compliance program, manufacturers reduce property damage and protect workers. Regular reviews of systems, updates to automation logic and validation of detection of smoke and flames complete the loop between detection and action.

FAQ

What is the difference between smoke detection and thermal sensors?

Smoke detection senses particles of combustion in the air while thermal sensors detect temperature changes. Smoke detection is best for smouldering events; thermal sensors spot overheating before smoke appears.

When should a manufacturer use aspirating systems?

Aspirating or air sampling smoke detection suits high-value or high-risk areas with hidden smoulder risks. Use it where the earliest possible warning matters, such as server rooms or powder storage.

How do camera analytics reduce false alarms?

Camera analytics add visual confirmation and context so operators can verify a trigger quickly. When models run on edge, they filter benign motion and focus on signs like smoke plumes or temperature anomalies.

Are there standards I must follow for detector placement?

Yes. NFPA and EN standards guide detector placement, testing and maintenance to meet life safety objectives. Follow those codes and local rules for compliance and audit readiness.

Can existing CCTV be used for early fire detection?

Yes. Platforms that convert CCTV into sensors can stream events and integrate with alarm systems. Visionplatform.ai enables this approach while keeping data on-prem and auditable.

What role does maintenance play in detection reliability?

Routine testing and calibration keep detectors within tolerance and reduce false alarms. Proper records and scheduled replacement of sensing elements maintain proper operation.

How do systems handle flammable materials and combustible dust?

Designs combine photoelectric detectors, aspirating systems and thermal sensors to spot both particles and heat. Controls then limit exposure and trigger suppression if needed.

Can analytics identify problems before a fire develops?

Yes. Machine-learning models can detect temperature anomalies and process malfunctions that often precede a developing fire. Early warning from analytics supports proactive maintenance and fire prevention.

What is the best way to integrate fire alarms with facility controls?

Integrate detectors with control panels and building management so alarms trigger coordinated actions. Use standard protocols and ensure redundant power and verified communications.

How often should detection systems be audited?

Audit frequency depends on local regulations and site risk, but annual full audits and more frequent functional tests are common. Keep logs to demonstrate compliance and to support insurance assessments.