Introduction to PPE Detection and Workplace Safety

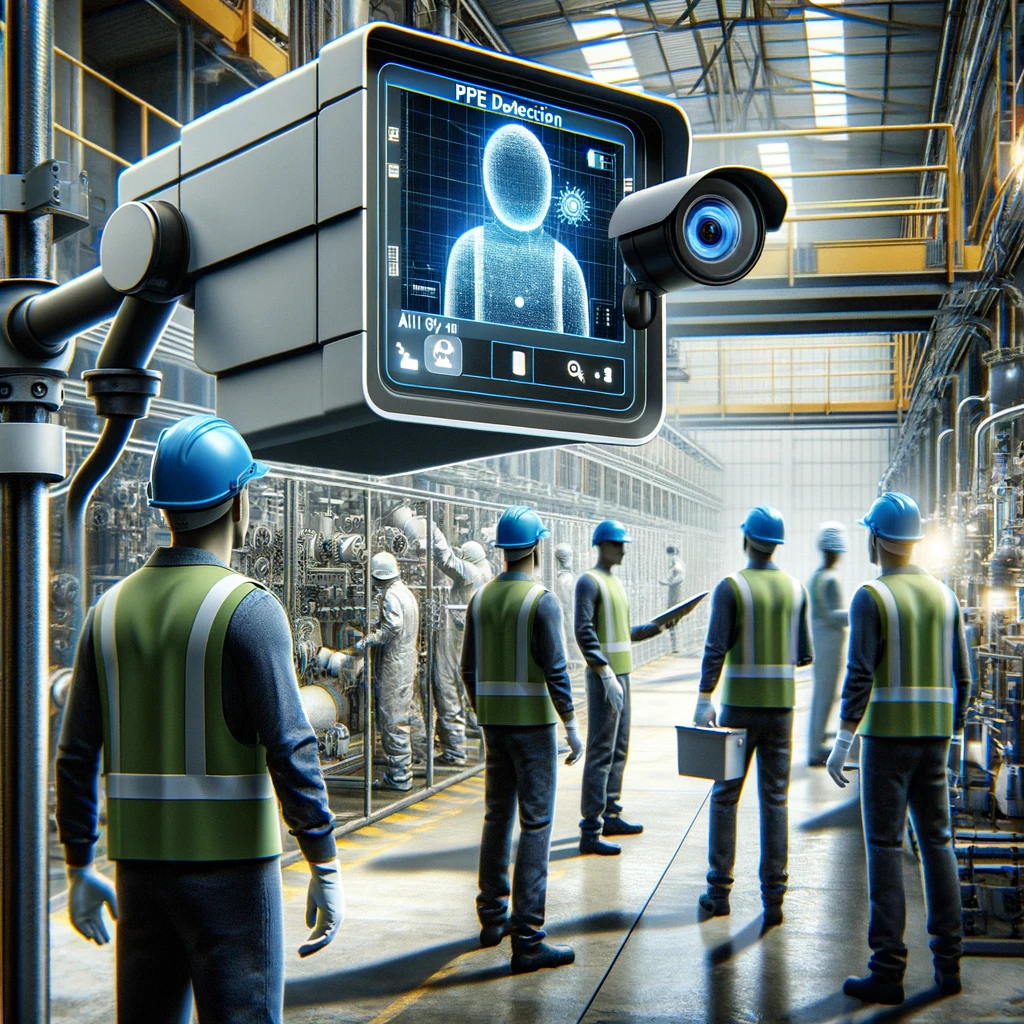

Personal Protective Equipment (PPE) detection plays a pivotal role in enhancing workplace safety, leveraging advanced AI to ensure that workers are wearing the required safety gear in real-time. By utilizing state-of-the-art computer vision algorithms, PPE detection technology can automatically identify safety items such as helmets, gloves, and high-visibility vests across various work environments. This functionality not only helps monitor PPE compliance but also significantly reduces workplace injuries by providing real-time notifications to safety managers.

The integration of AI algorithms into PPE detection systems allows for precise detection and monitoring of PPE usage. These systems utilize deep-learning algorithms to automatically analyze video feeds, enhancing the accuracy of PPE identification and ensuring a proactive approach to safety management. The ability of AI to detect non-compliance in real-time helps prevent hazardous exposures that could lead to serious injuries or fatalities.

Furthermore, the seamless camera integration and CCTV systems offered by modern PPE detection systems ensures that existing security infrastructures can be augmented without the need for extensive modifications. This ensures seamless integration within the existing workplace protocols, significantly enhancing the adaptability and efficiency of safety practices through the prediction of potential hazards. By automating the detection of PPE, companies can focus on other critical aspects of safety management, making workplaces safer and more compliant with occupational safety standards by utilizing prediction algorithms for potential hazards.

AI: Transforming PPE Compliance in the Workplace

AI-driven technologies are revolutionizing the way PPE compliance is monitored and enforced in the workplace. By harnessing the power of computer vision and advanced deep neural networks, AI technologies are able to detect and monitor the use of personal protective equipment in real-time. This capability is essential for maintaining high standards of workplace safety and ensuring that all safety protocols are followed diligently.

Real-time monitoring of PPE through AI-powered systems provides a host of benefits, including enhanced safety, reduced risk of workplace injuries, and improved compliance with safety regulations. These systems are designed to detect various types of PPE such as masks, gloves, and safety glasses, using sophisticated object detection algorithms that ensure high accuracy and minimal false positives.

Moreover, the proactive safety features of AI-driven PPE detection help to identify potential non-compliance before it results in an incident. This predictive capability is crucial in high-risk environments like construction sites and manufacturing facilities where the timely detection of missing PPE can prevent accidents and enhance worker safety. The functionality of AI in these systems allows for the generation of actionable insights that safety managers can use to implement immediate corrective measures, enhancing hazard prediction and compliance.

Additionally, AI enhances PPE compliance by enabling the integration of video analytics technology with existing camera and CCTV systems, ensuring that PPE detection is both efficient and non-intrusive. This integration plays a crucial role in the real-time assessment of workplace safety, allowing EHS professionals to maintain continuous surveillance without disrupting the daily operations of the workplace. The adoption of these AI-powered systems underscores a shift towards a more automated and responsive approach to safety management, paving the way for smarter, safer work environments.

Types of PPE Essential for Workplace Safety

Personal Protective Equipment (PPE) is crucial in safeguarding workers across various sectors, particularly in hazardous environments. Essential types of PPE include hard hats, safety glasses, gloves, and high-visibility vests, each serving a specific function to protect against workplace injuries. For instance, hard hats are mandated on construction sites to protect against head injuries, while safety glasses shield eyes from flying debris and hazardous chemicals.

The integration of automated PPE detection systems helps ensure worker safety by using state-of-the-art computer vision algorithms to monitor the proper usage of these safety gears. Leveraging deep learning, these systems can detect non-compliance and immediately alert safety managers, thus fostering enhanced safety protocols and proactive safety management. For example, if a detected person at a high-risk site is not wearing the required safety gear, real-time processing triggers an alert, enabling immediate corrective action.

Moreover, the deployment of these detection systems often involves seamless camera and CCTV integration, allowing them to become a part of the existing security infrastructure effortlessly and ensuring comprehensive safety gear detection. By continuously monitoring PPE compliance, these AI-powered technologies not only help prevent potential injuries but also play a crucial role in maintaining comprehensive safety management standards within the workplace.

Real-Time PPE Usage Monitoring with AI-Driven Technologies

AI-driven technologies are revolutionizing real-time PPE usage monitoring, employing advanced AI to detect and monitor compliance dynamically, including the precise detection of safety gear and the prediction of potential risks. These systems utilize machine learning and computer vision algorithms to identify whether factory workers or construction personnel are wearing the necessary personal protective equipment like masks, gloves, and helmets. This capability is crucial for ensuring safety and adherence to regulatory safety rules in real-time.

The core technology behind this functionality includes object detection and neural networks that analyze video feeds from workplace cameras. These systems can identify specific body parts and confirm whether the correct PPE is worn, effectively enhancing safety gear detection. For instance, detection systems can specifically look for helmets and safety glasses on workers performing tasks at heights or in other high-risk conditions, thereby checking whether employees are wearing hard hats and the necessary safety gear.

Real-time notifications are a significant advantage of AI-powered PPE detection. These alerts provide immediate information to EHS professionals about non-compliance and other safety issues, allowing for swift intervention. Additionally, the use of cloud-based platforms enables the integration of video analytics across multiple sites, enhancing the security and privacy of the data processed.

By taking advantage of cutting-edge AI technologies, companies can not only comply with safety protocols but also adopt a proactive approach to workplace safety. This helps in significantly reducing the risk of workplace injuries and ensures a safer work environment through continuous monitoring and immediate response to any PPE-related discrepancies.

Enhancing PPE Detection Technology for Seamless Camera Integration

Seamless camera and CCTV integration is fundamental to enhancing PPE detection technology, ensuring that systems can easily be embedded into existing security frameworks without disrupting workplace dynamics. Visionplatform.ai plays a pivotal role in this process, utilizing cutting-edge technology to merge real-time PPE monitoring with standard security operations effortlessly. This integration is crucial in hazardous environments where safety is paramount and non-compliance with PPE regulations can lead to serious workplace incidents.

The proactive approach adopted by Visionplatform.ai involves the use of advanced AI algorithms that not only detect but also analyze the video resolution and brightness to ensure that the PPE detection is effective under various lighting conditions. Through the use of edge computing and visionplatform.ai you can turn any existing ”old” camera into an AI camera. The technology utilizes bounding boxes to accurately locate and identify individuals within the camera’s field of view, marking a significant advancement in object recognition capabilities.

Moreover, collaborating with IT and security teams, Visionplatform.ai ensures that the integration respects both security and privacy concerns, embedding necessary safeguards and compliance protocols. This strategic collaboration is essential for maintaining the integrity and security of the data being processed, thus reinforcing the trust and reliability of the PPE detection systems deployed across industries.

Case Study: PPE Detection at Construction Sites

Construction sites represent high-risk environments where the adherence to safety protocols is critically important. Through the deployment of AI-powered PPE detection systems, construction companies have been able to significantly enhance worker safety and compliance. These systems actively monitor and detect the use of required safety gear such as helmets, goggles, and vests, ensuring that all personnel are adequately protected.

One of the key features of this technology is the use of unique IDs for each detected person, which allows for tracking of PPE usage over time and across different areas of the site. This feature is invaluable for conducting audits and ensuring that all workers are consistently following safety rules, including the correct wearing of hard hats and other PPE items. Moreover, the real-time processing capabilities of these systems mean that site managers can receive immediate notifications if a worker enters a hazardous area without proper PPE, enabling quick corrective action to be taken.

Visionplatform.ai’s implementation of these detection systems at construction sites has proven to be highly effective. By taking advantage of high video resolution and optimized brightness settings, the technology ensures accurate detection under diverse operating conditions. The success of this proactive approach highlights the critical role that advanced technology plays in transforming traditional safety management practices and safeguarding workers in dynamic and potentially dangerous environments.

Safety Management Through AI-Driven PPE Detection in High-Risk Industries

AI-driven PPE detection is transforming safety management in high-risk industries by ensuring that workers adhere to required safety protocols efficiently. These industries, where the risk of accidents and injuries is elevated, greatly benefit from the exclusion of human error in monitoring safety gear usage. AI technologies facilitate the automated detection of safety equipment, significantly reducing the chances of non-compliance going unnoticed.

This technology leverages advanced algorithms to monitor areas where high levels of protection are crucial, such as in chemical plants or metal foundries. Here, the presence of helmets, gloves, and protective suits is critical. The AI system’s ability to provide real-time alerts ensures that any lapses in PPE usage are addressed immediately, thereby maintaining a continuous enforcement of safety measures. This capability is vital for preventing workplace injuries and enhancing overall safety management.

The strategic implementation of these AI systems also involves taking advantage of existing camera infrastructure, which allows for a cost-effective expansion of safety monitoring capabilities without the need for extensive new installations. By integrating AI with current security technology, industries can enhance their safety protocols while ensuring seamless operation and compliance monitoring.

Working at Heights: Ensuring Compliance with Safety Rules

Working at heights is one of the most hazardous tasks in industries such as construction and maintenance, making strict compliance with safety rules imperative for hazard management. AI-driven PPE detection systems play a crucial role in this context by ensuring that all personnel are equipped with the necessary safety gear, such as harnesses, helmets, and non-slip footwear. These systems take advantage of high-resolution cameras and machine learning algorithms to accurately detect the presence and proper use of such equipment in real-time.

The detection systems are particularly beneficial in environments where manual monitoring is challenging due to the scope and nature of the tasks being performed. For instance, on large construction sites, it is impractical for supervisors to continuously monitor every worker manually. AI technologies bridge this gap by providing constant surveillance and immediate feedback on safety compliance, including the check whether workers are wearing hard hats and other PPE items.

Moreover, the implementation of AI-driven safety measures allows companies to take advantage of enhanced data analytics for PPE items. By analyzing the data collected from various sensors and cameras, safety officers can identify patterns in non-compliance and develop targeted interventions to address these issues. This proactive approach not only ensures the safety of workers operating at heights but also supports a culture of safety that prioritizes prevention over reaction, leading to better overall safety outcomes and compliance with stringent industry regulations.

VisionPlatform.ai: Pioneering AI-Driven PPE Detection

VisionPlatform.ai is at the forefront of revolutionizing workplace safety through its innovative use of a vision platform designed to enhance PPE detection using state-of-the-art AI technologies. By integrating advanced AI with a vision platform, VisionPlatform.ai enables seamless detection and monitoring of personal protective equipment (PPE) in real-time, ensuring that all workers adhere to safety standards effectively.

This technology stands out because it not only detects but also analyzes and reports on PPE usage across various industries. The use of a vision platform allows for comprehensive coverage and detailed analytics, providing actionable insights that help improve safety protocols and reduce workplace injuries. VisionPlatform.ai leverages deep learning models and machine learning algorithms to identify and verify the correct use of helmets, gloves, goggles, and other PPE essentials accurately.

Furthermore, VisionPlatform.ai’s platform is designed for easy integration into existing security and surveillance systems, offering businesses a scalable and cost-effective solution to enhance their safety measures. This capability is crucial for industries operating in hazardous environments where real-time PPE detection can significantly impact overall safety outcomes.

The Future of Workplace Safety: Advancements in AI-Driven PPE Detection

As we look towards the future, advancements in AI-driven PPE detection are set to transform workplace safety even further. VisionPlatform.ai continues to play a crucial role in this evolution, driving innovation with its vision platform that not only enhances current detection capabilities but also paves the way for new safety features.

The ongoing development of more sophisticated AI algorithms promises to improve the accuracy and speed of PPE detection, enabling real-time interventions that were not possible before. Additionally, the integration of IoT devices and smarter analytics frameworks through a vision platform will allow for more dynamic monitoring and control of safety measures across multiple locations.

These advancements are also expected to foster a more proactive safety culture within organizations. By providing earlier warnings and more precise data on PPE compliance, companies can prevent accidents before they occur, thereby minimizing risk and enhancing worker protection. Moreover, as these technologies become more integrated into everyday safety practices, they will enable continuous improvement through learning algorithms that adapt and optimize based on real-world data.

VisionPlatform.ai is well-positioned to lead these changes, offering a vision platform that encapsulates cutting-edge technology and innovative solutions to ensure that workplace safety is never compromised. The potential for these technologies to integrate seamlessly with existing systems and to provide new layers of security and efficiency illustrates a promising future for AI in enhancing occupational health and safety globally.

Frequently Asked Questions About PPE Detection

PPE (Personal Protective Equipment) detection technology is revolutionizing workplace safety by utilizing advanced AI to ensure compliance and prevent injuries. As industries increasingly adopt this innovative technology, questions arise regarding its functionality, benefits, and implementation. Below, we address some of the most common queries to help organizations understand and effectively integrate AI-driven PPE detection systems into their safety protocols.

What is AI-powered PPE detection?

AI-powered PPE detection employs advanced machine learning and computer vision technologies to automatically recognize whether workers are wearing required safety gear such as helmets, gloves, and protective glasses. These systems analyze video feeds in real-time, providing immediate alerts if PPE is not detected, thus enhancing compliance and reducing the risk of workplace accidents. Research shows that using such systems can decrease PPE non-compliance by up to 50% in high-risk industries.

How does PPE detection with AI enhance workplace safety?

AI-driven PPE detection systems enhance workplace safety by providing continuous, real-time monitoring of safety gear usage, including a check whether personnel are wearing hard hats correctly. This technology significantly reduces human error in safety checks and can identify lapses in PPE usage immediately. For example, in sectors like construction or manufacturing, where the risk of injury is high, these systems can reduce PPE-related incidents by ensuring that all personnel wear the correct gear at all times, thereby preventing potential injuries or fatalities.

Can AI PPE detection systems identify specific types of PPE?

Yes, AI PPE detection systems are capable of identifying specific types of PPE with a high degree of accuracy, thereby enhancing safety gear detection capabilities. These systems use trained algorithms to recognize items like hard hats, safety vests, goggles, and respiratory masks, ensuring safety gear detection is accurate and reliable. They can distinguish between different types of PPE and assess their adequacy in real-time, which is critical for ensuring that workers are adequately protected according to industry-specific safety standards.

Why do companies fail to comply with PPE regulations?

Companies may fail to comply with PPE regulations due to several factors including negligence, lack of proper training, or inadequate supervision. A study found that up to 30% of workers might neglect PPE usage due to discomfort or the perceived inconvenience of wearing it. Additionally, employers might underestimate the necessity of regular PPE audits and updates, leading to outdated or insufficient protection gear that fails to meet safety standards.

What are the benefits of integrating AI PPE detection in high-risk environments?

Integrating AI PPE detection in high-risk environments offers significant benefits by ensuring that all workers are wearing the necessary safety equipment, thus minimizing the risk of accidents. For instance, in industries like mining and construction, AI PPE detection can reduce the occurrence of severe injuries by up to 40% by enforcing strict adherence to safety protocols, including the prediction of hazard areas. The real-time feedback provided by AI systems also aids in immediate rectification of non-compliance, enhancing overall workplace safety and compliance.

How reliable are AI PPE detection systems in real-world scenarios?

AI PPE detection systems have demonstrated high reliability in real-world scenarios, with accuracy rates often exceeding 90%. These systems are particularly effective in environments with consistent lighting and where PPE types are well-defined. For instance, on manufacturing floors and construction sites, where the risk factors are predefined, AI systems efficiently monitor and report compliance, significantly reducing the risk of PPE-related safety incidents.

What should companies consider when implementing AI-based PPE detection?

When implementing AI-based PPE detection, companies should consider factors such as the specific types of PPE required, the complexity of the work environment, and existing camera and network infrastructure. It’s crucial to ensure that the AI system can integrate seamlessly with the current technological setup and that it supports the detection of all relevant PPE types. Additionally, training for staff on how to interact with and respond to the AI system’s alerts is essential for effective implementation.

How can AI PPE detection systems adapt to different lighting and environmental conditions?

AI PPE detection systems can adapt to various lighting and environmental conditions through advanced algorithms that adjust parameters such as exposure, contrast, and color balance to optimize image quality. Modern systems are equipped with sensors that can modify settings in real-time to maintain high detection accuracy regardless of changes in natural or artificial lighting, ensuring consistent performance both indoors and outdoors.

Can AI PPE detection systems respect worker privacy?

Yes, AI PPE detection systems can be designed to respect worker privacy. Many systems incorporate features such as face blurring and anonymization to ensure that personal identifiers are not stored or processed. This approach allows companies to comply with privacy regulations while still benefiting from the safety enhancements provided by real-time PPE monitoring. Face recognition however is also possible to get the other side of the spectrum.

Where can companies find more information on implementing AI-driven PPE detection?

Companies looking to implement AI-driven PPE detection can find more information from technology providers specializing in AI safety solutions, industrial safety conferences, and through online resources that focus on technological advancements in workplace safety. Providers like Visionplatform.ai offer detailed case studies, whitepapers, and direct consultations to help organizations understand the capabilities and integration process of AI-driven PPE systems.